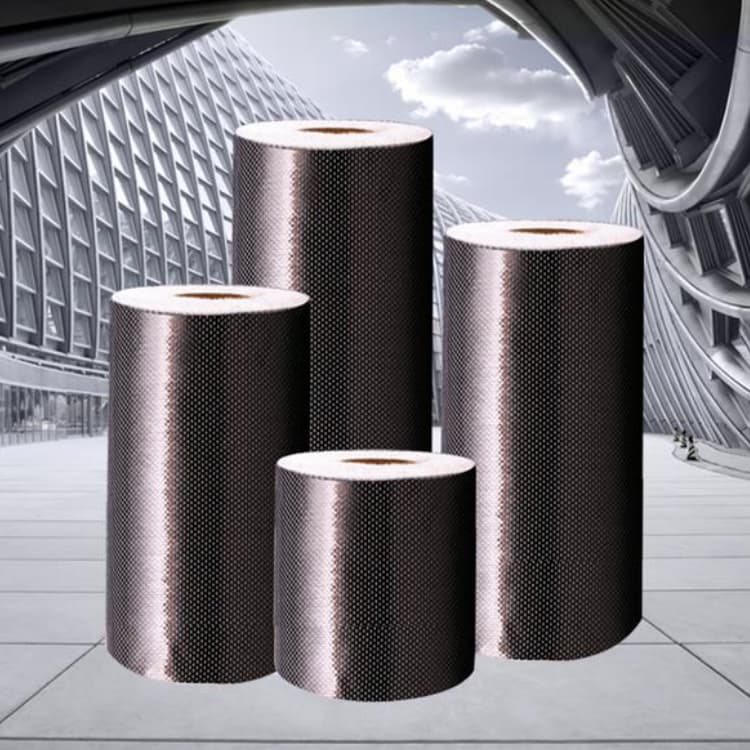

Beyond 2,600°F: Where Flexibility Meets Extreme Heat Protection

When your thermal application demands both bendability and brute-force protection, Aohong’s ceramic fiber cloth outperforms traditional solutions. Forget stiff ceramics – this aerospace-grade textile handles industrial punishment while flexing to fit.

🔥 Material DNA: What Makes It Tick

- ✓ 72% Al₂O₃ / 28% SiO₂ – beats ASTM C892 Class 3

- ✓ 2,300°F continuous (2,600°F emergency)

- ✓ 250 psi warp strength – won’t tear during install

- ✓ 1/16″ to 1/2″ thickness (±5% tolerance)

Foundry Secret: Lasts 40% longer than standard fabrics in aluminum ladle covers

Foundry Secret: Lasts 40% longer than standard fabrics in aluminum ladle covers

⚙️ Industry-Specific Muscle

Power Plants

- • UL-certified for turbines

- • Cuts boiler temps by 210°F vs metal

Aerospace

- • MIL-I-24244 compliant

- • 18% lighter than mica barriers

Foundries

- • Eats molten aluminum splash

- • Survives thermal shock cycles

🛡️ Safety You Can Feel

- ▸ Low bio-persistent fibers – ECHA compliant

- ▸ <3% shot content (won’t sandpaper your equipment)

- ▸ Vermiculite option – keeps dust in check

✂️ Your Design, Our Precision

- ✓ Die-cut to ±0.02″ – tighter than laser cutting

- ✓ Silicone or acrylic binders – your choice of stiffness

- ✓ Conductive versions – stops static cold

✅ Why Aohong Wins

“We switched after a competitor’s blanket crumbled during outage repairs. Aohong’s cloth survived three furnace rebuilds – still going.”

Plant Manager, Ohio Steelworks

🚫 The No-Compromise Zone

For thermal engineers who can’t afford failures, Aohong’s ceramic fiber textiles deliver where others crack. Literally.

MIL-I-24244

ECHA Annex XVII

Hongwo Thermal Insulation Material

Hongwo Thermal Insulation Material

Scan the QR Code to start a WhatsApp chat with us.