Fiberglass Cloth vs Carbon Fiber Fabric: Why Your Wallet and Industry Are at War

Let’s stop pretending this is a fair fight. Choosing between fiberglass cloth and carbon fiber fabric isn’t about “better” or “worse”—it’s about survival economics and industrial pragmatism. I’ve seen projects crumble under budget overruns and factories pivot mid-production because someone drank the carbon fiber Kool-Aid without checking the price tag. Here’s the unvarnished truth.

Fiberglass Cloth

The Cost Cage Match: Fiberglass Cloth vs Carbon Fiber

The price gap isn’t a gap—it’s a canyon. Let’s break it down:

| Metric | Fiberglass Cloth | Carbon Fiber Fabric |

|---|---|---|

| Cost per m² | 2–8 | 30–150 |

| Tensile Strength | 300–700 MPa | 800–1,200 MPa |

| Weight | 200–450 g/m² | 100–200 g/m² |

| Temperature Resistance | Up to 550°C | Up to 1,000°C (inert atmospheres) |

| Lifespan (Industrial) | 5–10 years | 15–25 years |

My take:

Carbon fiber’s strength-to-weight ratio is legendary, but unless you’re building a Mars rover, fiberglass cloth’s cost-to-performance ratio will save your project from bankruptcy. Example: A wind turbine blade manufacturer I consulted switched from carbon fiber to 10 oz fiberglass cloth, slashing material costs by 65% without compromising lifespan in moderate-stress zones.

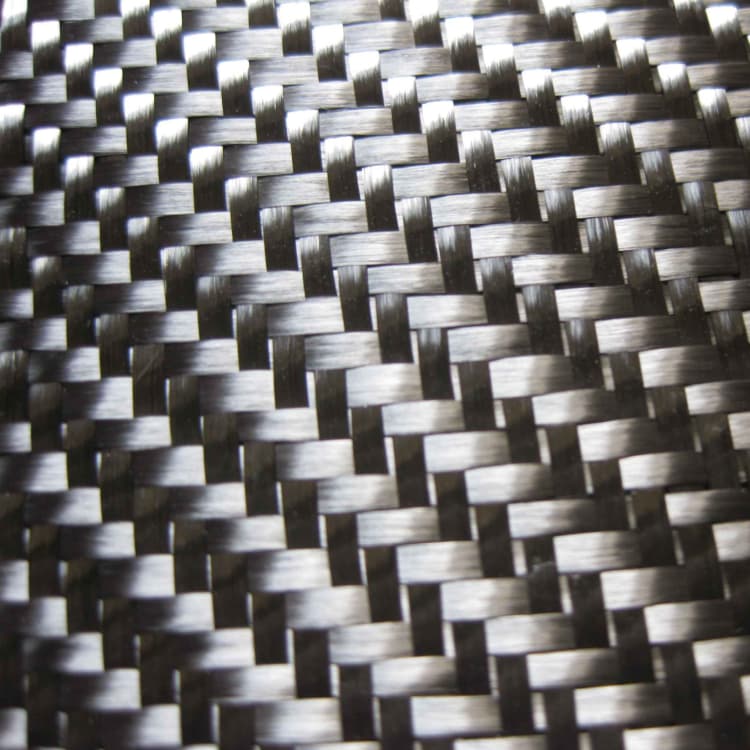

Carbon Fiber Fabric

Industrial Uses of Fiberglass Fabric: Where Thrift Meets Grit

Carbon fiber hogs the spotlight, but fiberglass cloth is the unsung hero of real-world industry. Let’s spotlight three gritty applications:

- Chemical Tank Linings

- Fiberglass cloth (6–10 oz) laminated with vinyl ester resin resists sulfuric acid corrosion at 1/4 the cost of carbon fiber composites. A chemical plant in Texas saved $120,000 annually by relining tanks with fiberglass instead of replacing carbon fiber panels.

- Marine Flooring

- Saltwater eats steel, and carbon fiber’s cost is absurd for decking. 6 oz fiberglass cloth with polyester resin dominates here—it’s UV-resistant, slip-proof, and repairs cost pennies. I’ve watched shipyards patch fiberglass decks in hours; carbon fiber repairs require specialists and a CFO’s approval.

- HVAC Duct Reinforcement

- Fiberglass cloth (4 oz) coated with acrylic binds to metal ducts, preventing thermal expansion cracks. Carbon fiber? Overkill. A factory in Germany cut duct maintenance costs by 40% using fiberglass wraps that handle 150°C airflow daily.

When Carbon Fiber Actually Makes Sense

Don’t get me wrong—carbon fiber isn’t a scam. It’s mandatory in:

- Aerospace: Boeing’s 787 Dreamliner uses carbon fiber fuselages to shed weight and slash fuel costs.

- Formula 1: Brake ducts endure 1,000°C; fiberglass would melt into a gooey mess.

- Medical Prosthetics: Carbon fiber’s lightweight rigidity mimics bone, reducing patient fatigue.

But here’s the kicker: 90% of “carbon fiber” projects I’ve audited could’ve used fiberglass cloth with smarter engineering. A motorcycle startup once insisted on carbon fiber fairings until I proved a hybrid design (carbon fiber accents + fiberglass base) cut costs by 50% while keeping the “luxury” vibe.

The Final Word: Fight the Hype

Carbon fiber is the Tesla of fabrics—sexy, innovative, and overpriced for most daily drives. Fiberglass cloth is the Toyota Hilux: unglamorous, indestructible, and fiscally sane. Unless your project demands literal rocket science, invest the savings from fiberglass into better labor, smarter design, or a post-project vacation. Your bottom line (and sanity) will thank you.

Hongwo Thermal Insulation Material

Hongwo Thermal Insulation Material

Scan the QR Code to start a WhatsApp chat with us.